Understanding the Issue

Drives often include output voltage limits to protect against transient voltage spikes, which can damage equipment or cause instability. These protective measures keep voltage within a safe range, preventing sudden fluctuations that may lead to failures.

Some applications need a drive to step down from 480V incoming to around 270V outgoing. While many drives support this, the H100+ has a minimum output voltage of 320V. This poses challenges for applications needing tighter voltage control for stability or protection.

Solution: Adjusting the Base Frequency

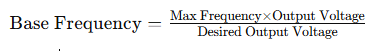

One way to work around this is by modifying the base frequency using:

Where:

- Max Frequency is typically 60 Hz.

- Output Voltage is 320V (minimum allowed).

- Desired Output Voltage is the required value (e.g., 270V).

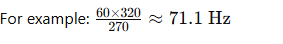

Since the drives are set at 60 Hz, software adjustments are needed to compensate. This shifts the voltage-to-frequency relationship to hit the desired voltage range.

Why Changing the Base Frequency Works

Drives follow the voltage-to-frequency (V/f) principle, maintaining a consistent ratio to ensure stable motor performance. Adjusting the base frequency shifts this ratio, allowing for lower voltage output without compromising torque or efficiency.

For instance, a default 60 Hz base paired with 320V can be scaled. Reducing the base frequency lowers the voltage output while keeping performance within safe, usable limits—no hardware changes required.